The Rise of Aluminum Aerosol Cans: Sustainable Solution Packaging

From the cluttered shelves of supermarkets to the beauty aisles of your favorite store, aluminum aerosol cans have become increasingly prevalent in packaging. Their popularity is not without reason. Lightweight, versatile, and easily recyclable, these cans have emerged as a sustainable solution for packaging a wide range of products.

Unlike their plastic counterparts, aluminum aerosol cans offer several environmental benefits. For starters, aluminum is a highly sustainable material that can be recycled indefinitely without losing its properties.

This means that every aluminum can you recycle can be transformed into a new can, reducing the demand for virgin materials and minimizing waste. Furthermore, aluminum cans require much less energy to produce compared to plastic ones, reducing greenhouse gas emissions.

Aluminum aerosol cans offer numerous environmental benefits, making them an attractive choice for brands and consumers alike.

The primary advantage lies in the recyclability of aluminum. Unlike plastic, aluminum can be recycled indefinitely without losing its properties.

This means that every aluminum can you recycle can be transformed into a new can, reducing the demand for virgin materials and minimizing waste.

Additionally, the recycling process for aluminum requires significantly less energy compared to plastic, resulting in lower greenhouse gas emissions.

Comparison with other packaging materials

When compared to other packaging materials like plastic and glass, aluminum aerosol cans have distinct advantages. Plastic packaging, although widely used, poses significant environmental challenges due to its non-biodegradable nature and harmful impact on marine life.

In contrast, aluminum cans are non-toxic and do not leach harmful chemicals into the environment. Additionally, aluminum cans provide better protection against light, air, and moisture, keeping products fresh and uncontaminated for longer periods.

Glass packaging, while recyclable, is heavier and more fragile than aluminum cans. This makes aluminum a preferable choice for brands looking to reduce transportation costs and minimize breakages during distribution.

Advancements in technology and design

The rise of aluminum aerosol cans can also be attributed to advancements in technology and design. Manufacturers are constantly innovating to improve the functionality and user experience of these cans.

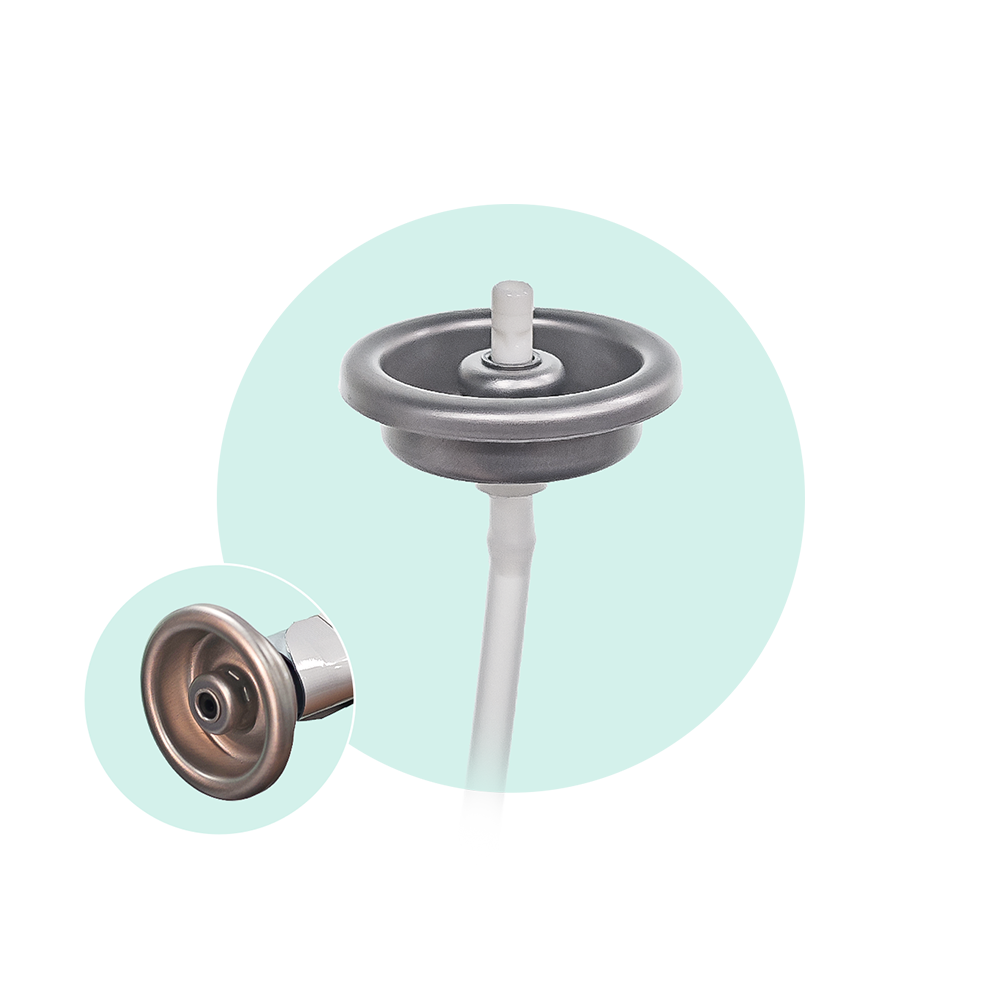

One notable development is the introduction of bag-on-valve (BOV) technology, which allows for the dispensing of products without the use of propellant gases. This eliminates the need for chemical propellants, making the packaging even more eco-friendly. BOV technology also enables the complete evacuation of product from the container, minimizing waste and ensuring that consumers get every last drop.

Furthermore, manufacturers are investing in research and development to enhance the recyclability of aluminum aerosol cans. Efforts are being made to improve the separation of different components, such as plastic caps and valves, to streamline the recycling process. These advancements not only contribute to a more sustainable packaging solution but also pave the way for a circular economy, where resources are reused and waste is minimized.

6.19-10-scaled-e1701937503313.webp)

Recycling and circular economy initiatives

To fully leverage the sustainability benefits of aluminum aerosol cans, recycling and circular economy initiatives play a crucial role. Governments, organizations, and individuals are actively working towards creating a closed-loop system for aluminum packaging.

In many countries, recycling programs have been established to encourage the proper disposal and recycling of aluminum cans. These programs include curbside collection, drop-off points, and incentives for recycling. The collected aluminum cans are then sent to recycling facilities where they are melted down and turned into new cans or other aluminum products. By participating in these recycling initiatives, consumers can contribute to reducing the demand for virgin materials and conserving valuable resources.

Furthermore, the concept of a circular economy aims to keep materials and products in use for as long as possible, minimizing waste and maximizing resource efficiency. Aluminum aerosol cans, with their recyclability and infinite reusability, are well-aligned with the principles of a circular economy. By adopting circular economy practices, the packaging industry can contribute to reducing environmental impact and creating a more sustainable future.

The future of aluminum aerosol cans in packaging

In a world where environmental consciousness is on the rise, the growth of aluminum aerosol cans comes as no surprise. Their sustainability benefits, practical advantages, and aesthetic appeal have positioned them as a preferred choice for packaging across various industries.

As consumer demand for sustainable packaging continues to increase, brands are likely to invest more in aluminum aerosol cans, further driving innovation and improvements in design and recyclability. Advancements in technology and the establishment of recycling and circular economy initiatives will contribute to the continued success of aluminum aerosol cans as a sustainable solution for packaging.

With their infinite recyclability, lightweight nature, and protective properties, aluminum aerosol cans are paving the way for a greener future. As more brands and consumers embrace these cans, we can expect a significant reduction in plastic waste, lower greenhouse gas emissions, and a more sustainable packaging industry as a whole.

The rise of aluminum aerosol cans is not just a trend but a reflection of our collective commitment to preserving the planet for future generations. Let’s choose aluminum aerosol cans and make a positive impact, one can at a time.