Uncover the Secrets of EBI Aluminum Packaging Molding Process

How is the production process for aluminum containers carried out? This question is extremely common. Both industry practitioners and consumers who buy this product are curious about the manufacturing process of aluminum containers.

In this article, I will introduce some of the production processes of aluminum containers in detail. Let’s discover and journey together.

overview

This article mainly introduces the forming process of aluminum aerosol cans, semi-automatic aluminum bottles, aluminum boxes, aluminum folding tubes, and other products.

The raw materials for producing this type of aluminum packaging product are aluminum alloy and pure aluminum. EBI uses only pure aluminum to make packaging to provide high-quality products that meet customer needs.

The following will introduce the molding process of different products separately.

Production process

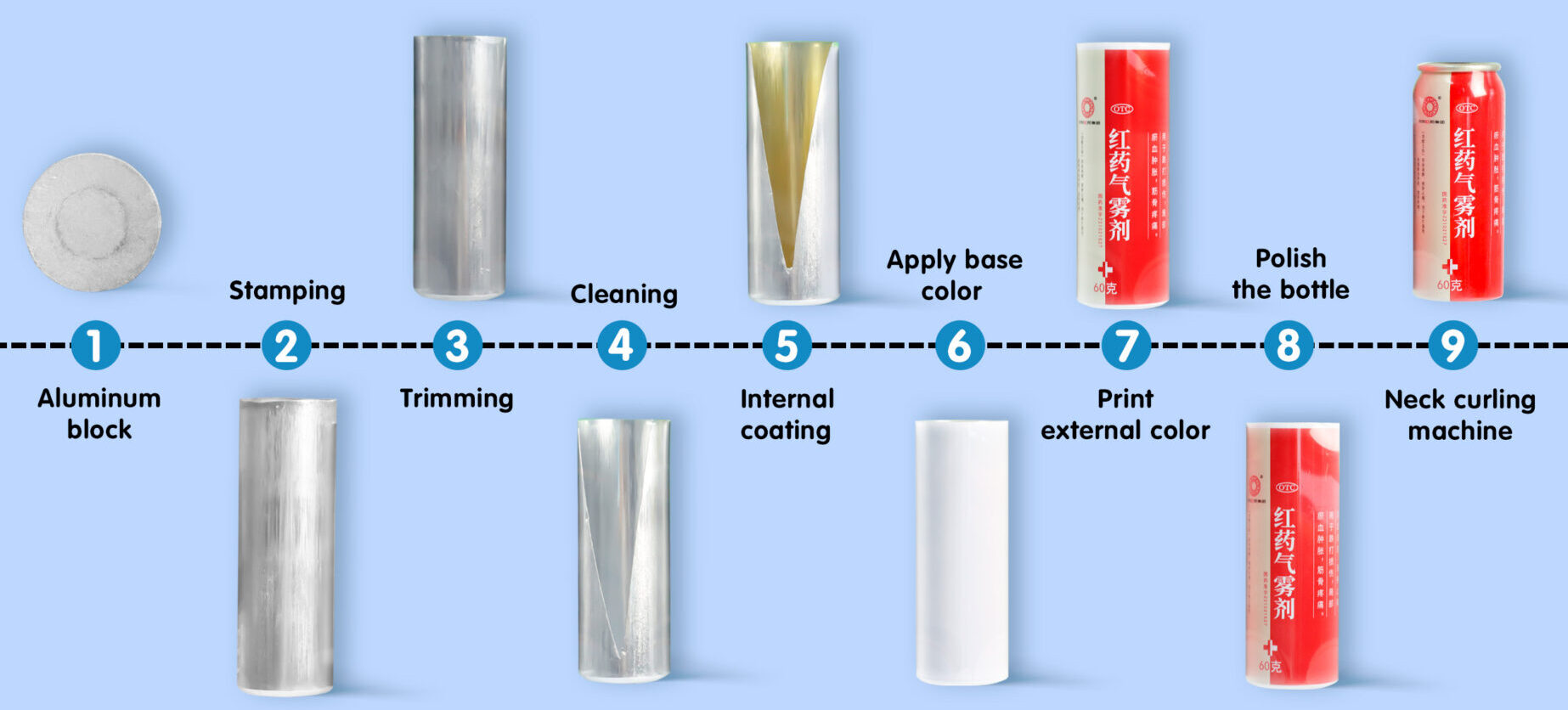

Aluminum Aerosol Can

Aluminum block

- The form can blanks through a punching machine

- Trim neatly with a trimming machine

- Clean with a can washing machine

- Paint inside

- The primer machine applies the base color to the can

- Print exterior color

- Polish the bottle

- Roll the neck with a necking machine

Before it becomes a round can, it is just a small aluminum disc. It utilizes fresh aluminum rather than reclaimed aluminum and subsequently undergoes a series of procedures to transform into a cylindrical aluminum can ultimately.

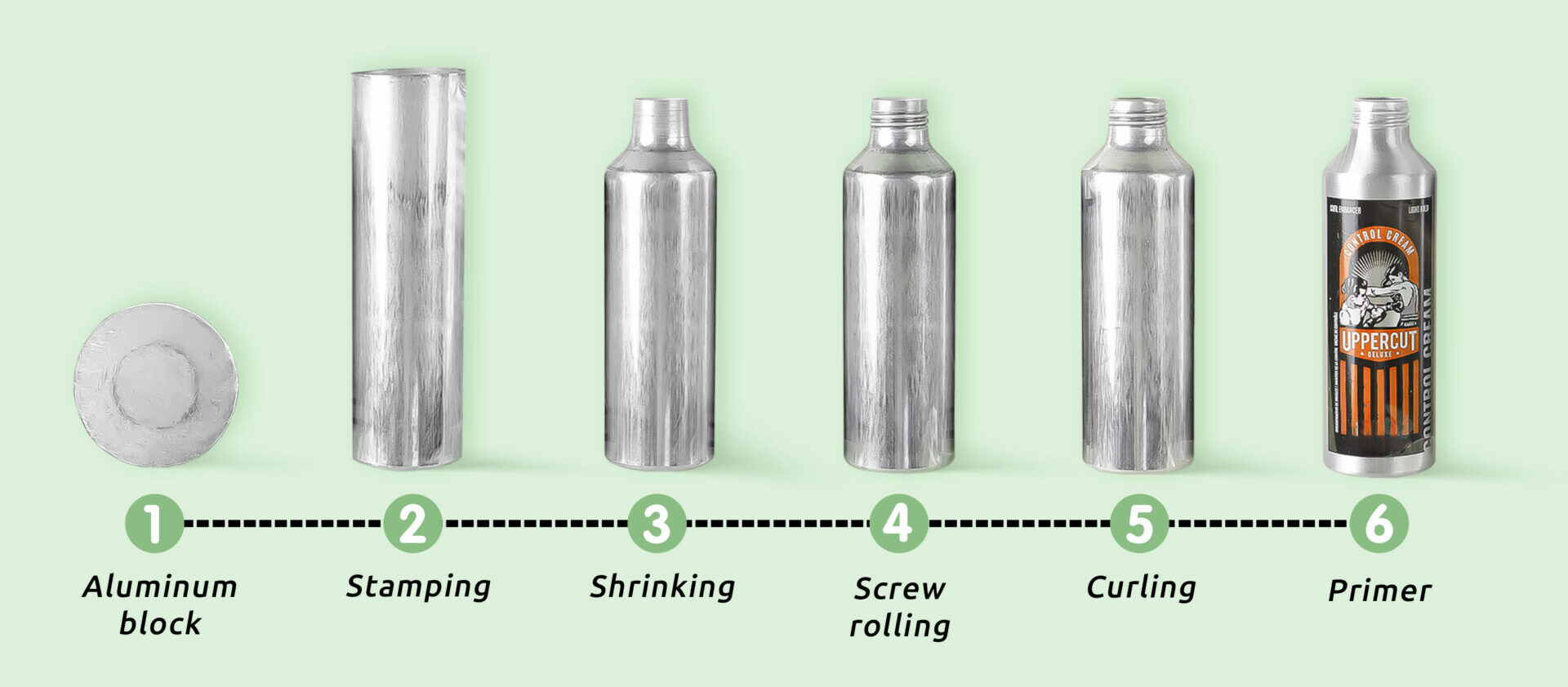

Aluminum Bottle

In the production process of aluminum bottles on the semi-automatic line, the raw materials are also new aluminum discs.

Aluminum disc

1. Stamping: Use a machine to stamp the aluminum block into a cylindrical can

2. Shrinking the mouth/mouth: Reduce the mouth and shoulders

3. Thread rolling: Roll the mouth

4. Curling: Roll the top of the mouth inward

5. Printing: Choose the printing method and style according to your requirements

It is worth noting that the above content is the production process of aluminum bottles on the semi-automatic line. The process sequence of aluminum bottles produced on the automatic line will be slightly different.

The automatic line produces aluminum bottles. After all the preparations are completed, printing is carried out first, and then the shoulder shrinking and screw thread rolling operations are carried out.

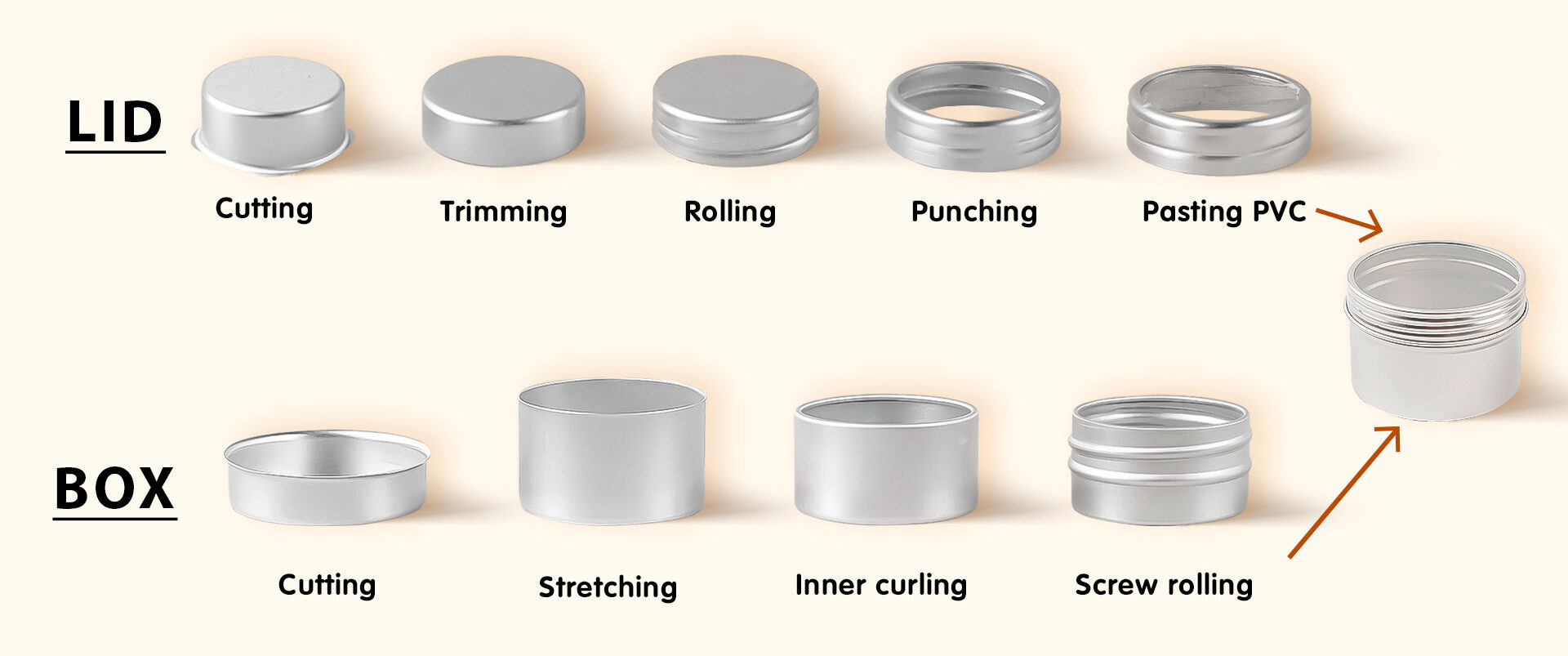

Aluminum Jar

The aluminum box molding process separates the lid and the box body. Aluminum box lids are divided into window type and threaded type (no window)

Lid

1. Cutting, prepare the aluminum material and start cutting

2. Trimming, trim the edges around the lid

3. Rolling, roll out the thread mouth

4. Punching, the window style needs to punch and remove the top

5. Paste PVC

Box

1. Cutting

2. Stretching, stretch according to the required size

3. Inward rolling, the mouth rolls inward

4. Rolling, screw rolling makes it easier to tighten the lid and box

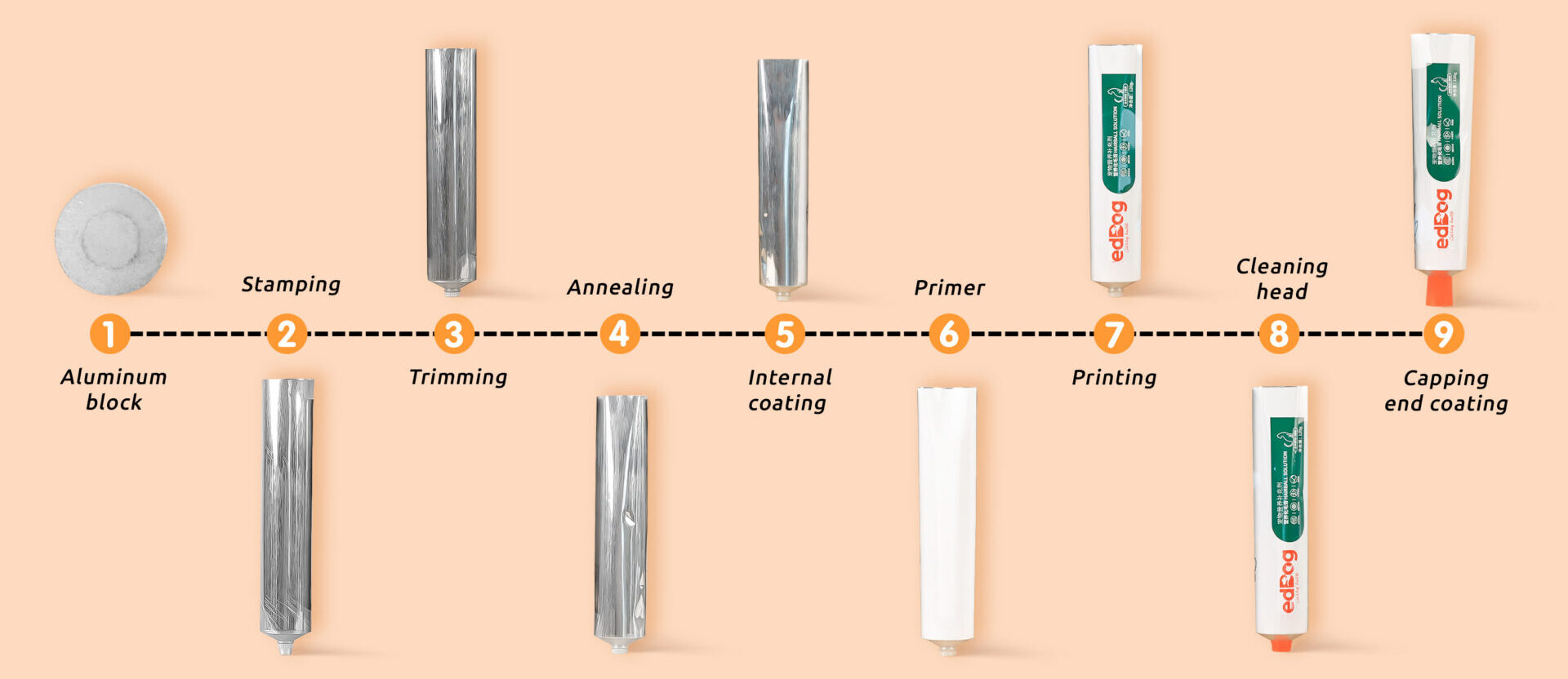

Aluminum Collapsible Tube

Aluminum disc

1. Punch to form a cylindrical tube

2. Trim to remove excess parts according to the required size

3. Anneal to cool the tube

4. Internal coating, apply the appropriate internal coating material according to the requirements

5. Primer, external coating for easy printing

6. Printing, select the printing process according to the requirements

7. Cleaning head, install different mouth materials according to the purpose

8. Screw cap/tail coating

Aluminum aerosol can

Product

Aluminum screw bottle

Product

Aluminum jar

Product

Aluminum collapsible tube

Product

Let's Talk Packaging!

- Phone: +86-0791-86372550

- Email: marketing@ebi-china.com

- WhatSapp: +86-18779223927

- Monday-Friday: 9 am to 6 pm

Saturday, Sunday: Closed - Address: 28th Floor, Section A, Yunzhongcheng, No.3399 Ziyang Avenue, Nanchang, Jiangxi China