Aluminum aerosol can

MOQ: 30,000 pcs

Capacity: 15ml – 700ml

Mouth: 25.4mm,20mm

Logo printing: offset printing(6-9 colors)

EBI special design

Recommended index:

we can offer artwork design and engineering services, different bottle shapes and printing designs can be customized as per your request.

SGS certified food grade

approved Epoxy inner coating

with EU standard

30-45 days

Customizable aluminum aerosol cans

These consumer-friendly aerosol cans have high safety and hygiene approval standards. They are also environmentally friendly and sustainable, which means they are recyclable, conserve resources, comply with today’s ecological requirements, and lead trends. They have an attractive design and appearance, made even more unique due to the excellent properties of aluminum.

Our production lines, equipped with printing machines of up to 9 colors, allow different lacquers and finishes to be applied. we can offer a wide range of sizes from 15 ml to 700 ml with diameters ranging from 22mm to 66mm.

We are flexible with a MOQ of 10,000 pieces to meet start-up companies’ requirements.

EBI has three factories for aluminum aerosol cans. The advantages of the first factory are good product quality, a variety of special-shaped aerosol cans, and a large number of sample stocks. Customers can choose any style they like, and samples can ensure fast delivery.

The aluminum aerosol cans we provide have a variety of internal spray materials, including gold epoxy phenolic, polyimide, and food-grade internal coating. The selection of different materials will be based on the customer’s perspective, and the internal coating will be selected according to the purpose required by the customer.

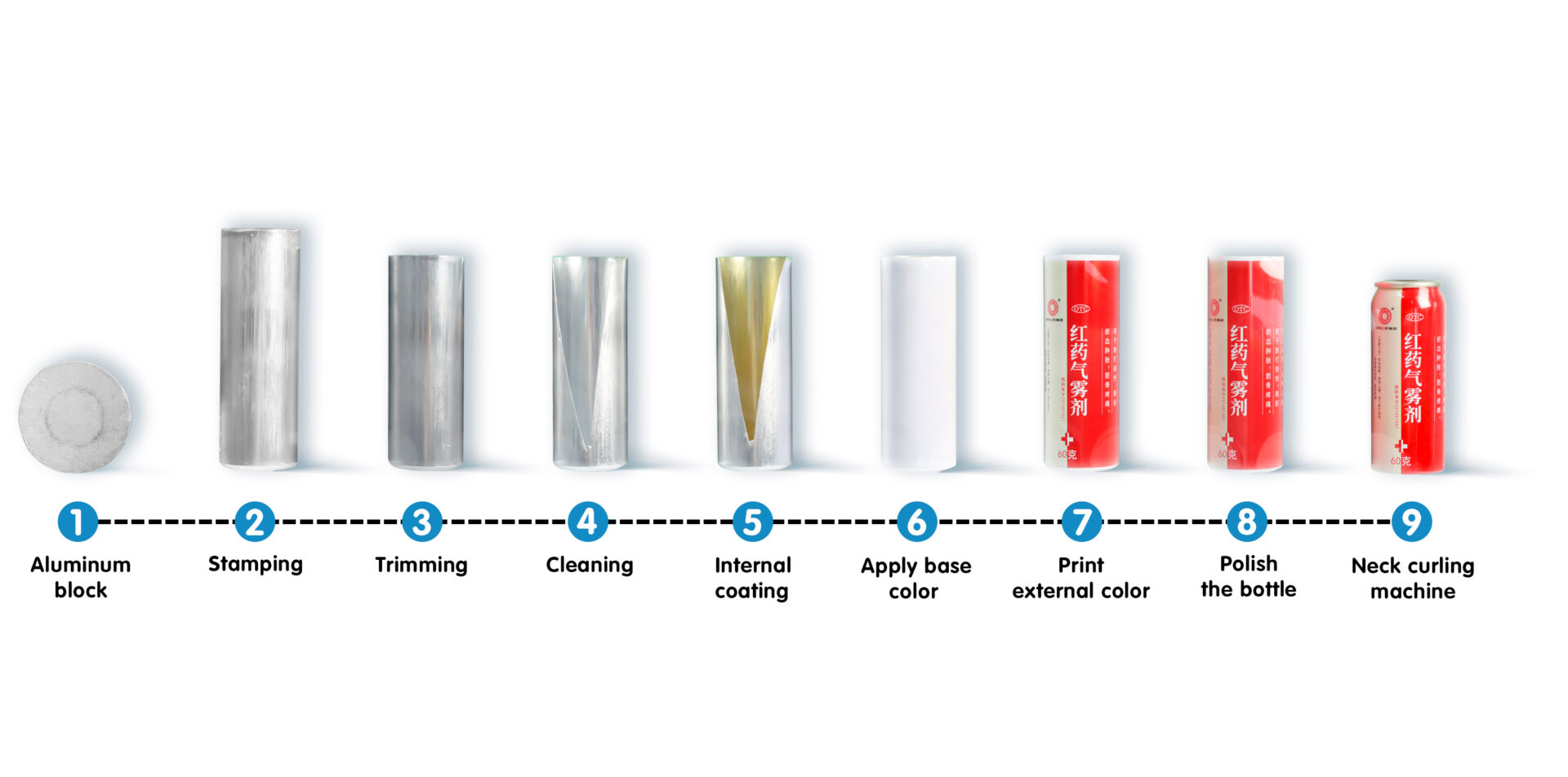

Aluminum Aerosol Can Manufacturing Process

This is the aluminum aerosol cans manufacturing process in our automatic line factory, from aluminum discs to final molding into aluminum cans. Each process is completed automatically by the machine, which shows its precision. Moreover, EBI’s aluminum supply has several advantages: small minimum order quantity, fast delivery, and many shoulder types.

The wide range of shoulder and body shapes available for aluminum aerosol cans provides another argument for this packaging form being chosen in large numbers. Aluminum’s good formability combined with flexible impact extrusion technology is also ideal for small batch production, allowing aluminum cans to be produced in as many sizes, shapes, and print formats as possible without significantly reducing production in the manufacturing process speed.

In addition to the classic cylindrical jar body and rounded shoulders, there are now more and more waisted or upward-tapering jars with pointed, peaked, or flat shoulders. Different shapes can extend almost the entire length of the can.

Proven safety technology - no leaks

We have proven techniques to ensure the safety of aerosol cans for special market requirements.

- As for the mouth of the aerosol cans, we can make the secondary machining on the curl, to make it more flat than the usual design, it can enhance the tightness matching with the valve.

- For aluminum oxygen cans, I will require much higher pressure. The thickness is .3-0.5 mm for normal aluminum aerosol cans, and the deformation pressure is 14-18 bars, we can make the aerosol can in wall thickness of 0.6 mm to improve the deformation pressure to 25-32 bars, which can be widely used for oxygen and fire extinguisher.

One-stop solution for aluminum aerosol cans, actuators and valves

There is a wide range of closures, spray tips, and ingenious dispensing systems in use for aluminum aerosol cans. They all ensure precise application of the can contents and equally precise dosing of the respective product. At the same time, direct contact of the packaging with potentially contaminated surfaces is avoided.

Caps and spray tips also often provide a visual difference from competing products. Properly designed, they harmoniously complete the overall appearance of the can, making it more valuable and elegant.

By combining different spray tips and caps, the aerosol can itself can also have a wider range of uses.

Aerosol cans are easy to use and convenient for hundreds of products used daily. By using an aluminum aerosol can packaging for your products, you can ensure they are securely and hygienically packed -leading to a long product life. Aluminum aerosol cans are 100% infinitely recyclable, this can help your brands to be more socially responsible and good to our earth.

Aluminum aerosol cans can be used widely for personal care, health care, household products, cosmetics, and pharmaceuticals. Our R&D team can design and develop different shapes according to customer requirements to differentiate their products on the shelf.

Let's Talk Packaging!

- Phone: +86-0791-86372550

- Email: marketing@ebi-china.com

- WhatSapp: +86-18779223927

- Monday-Friday: 9 am to 6 pm

Saturday, Sunday: Closed - Address: 28th Floor, Section A, Yunzhongcheng, No.3399 Ziyang Avenue, Nanchang, Jiangxi China